Industry Solutions

MOLI delivers manufacturing intelligence tailored to your industry's unique requirements and quality standards.

Assembly & Machining

Ensure operator competency validation, real-time work instruction delivery, and complete traceability. MOLI's training features support ISO 9001 and AS 9100 requirements while reducing the burden of compliance.

Injection Molding

Manage complex process parameters and maintain process control documentation. Built-in competency management ensures only certified operators handle critical molding operations and aligns with ISO 13485 for medical device manufacturers.

Optics & Photonics

Precision manufacturing demands precision workforce management. MOLI tracks clean room protocols, coating specifications, and assembly procedures while ensuring operators maintain current certifications for optical testing and metrology.

Quality System Integration

Whether you have ISO certification, are pursuing ISO certification, or simply want world-class operations, MOLI's built-in compliance tools streamline the human elements of quality management:

Training Management

Automated competency tracking, certification reminders, and skills gap analysis across all ISO standards.

Communication Control

Structured information flow ensuring critical updates reach personnel instantly.

Documentation Automation

Generate compliance reports, maintain training records, and track corrective action.

Competency Validation

Real-time verification that only qualified operators perform critical tasks, and that all operators received the correct instructions.

ISO 9001 and ISO 13485 certified plastics facility

Machine, Equipment & Hardware Integration

MOLI connects directly to your existing machines and equipment, eliminating manual data entry errors and automating documentation.

Measurement Devices

Direct integration with scales, moisture analyzers, and metrology or testing equipment via serial port / USB / RS-232. Eliminate paper receipts and prevent documentation findings where operators forget to record date / time / location.

Environmental Monitoring

Automated environmental sensors replace the "clipboard next to a hygrometer" workflow. Continuously capture temperature, humidity, and pressure data without supervisor intervention.

Machine Connectivity

Direct connection to EOS 3D printers via EOSCONNECT and Arburg injection molding presses through ALS. Gain visibility with automatic shot counts, print status, process parameters, and machine states.

The Result: Eliminate paper receipts, prevent documentation errors, and ensure every measurement taken includes proper date / time / location / operator identification automatically.

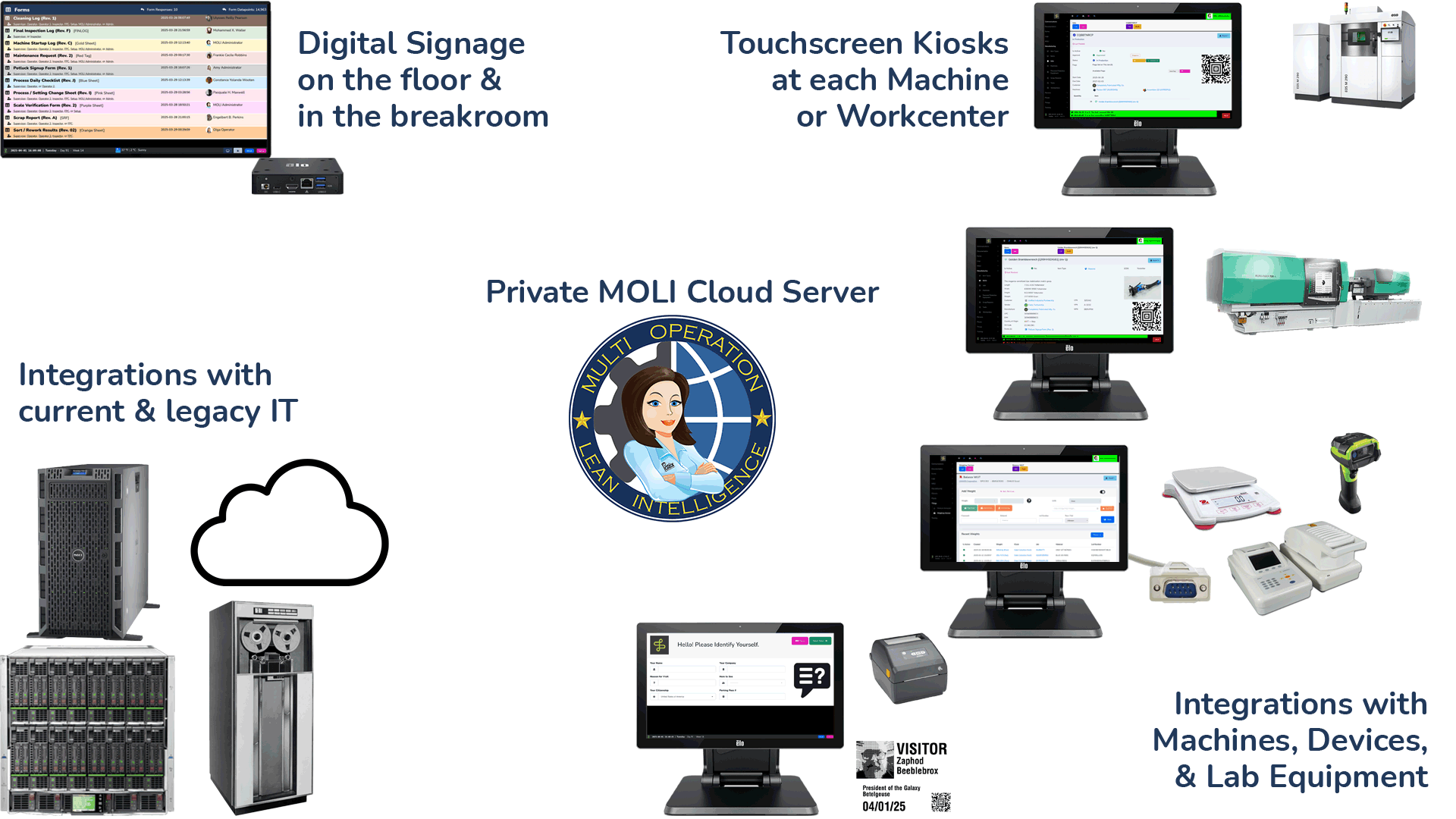

MOLI Topology